Obuu was born thanks to the research and innovation in the aerospace maintenance industry by their three cofounders, so we keep this spirit alive and continue innovating in the engineering field.

Obuu was born thanks to the research and innovation in the aerospace maintenance industry by their three cofounders, so we keep this spirit alive and continue innovating in the engineering field.

TIANA

TECNOLOGÍAS INDUSTRIALES PARA UNA AREUNÁUTICA SOSTENIBLE Y COMPETITIVA

Subsidised by CDTI

As an evolution of the TEMACON Project, Airbus continues to trust in the capabilities of OBUU to follow up on the research and development of a dimensional validation system for composite parts with low structural rigidity, and flexible geometry,by designing an automatic validation process that compares measured parts with 3D scanner with nominal geometries to discern whether the parts are within admissible tolerance, without the need of specific support tools

OBUU, in partnership with AIRBUS, embarks on this new project to continue the evolution of what can be a radical breakthrough in the dimensional quality check stages of composite part manufacturing processes.

Once again, OBUU provides its dilated expertise in:

– Design, manufacture and structural behavior of composite materials.

– Wide range of Metrology and CAD digital tools.

– Optimization of industrial processes through the development of digital products including advanced mathematical models and algorithms.

TEMACOM

(Project funded by RIS3 strategy from Comunidad de Madrid)Carbon fiber aero-parts, by its very nature, the pieces of this material are deformed unpredictably during their curing process, altering their tolerances and putting at risk the viability of the final assembly. Currently, to avoid these problems, big specific tools are used for each piece involving a high economic cost and time for the manufacturing process.

For this reason, during four years in partnership with AIRBUS, OBUU will work on the research and development of a system of dimensional validation for parts made of composite by designing an automatic measurement process and the creation of a mathematical model that predicts the behavior of the material in the presence of external forces. To reach this milestone, obuu will make use of its experience in:

• Composite materials, in terms of design, manufacture and structural behavior.

• Dimensional metrology, to choose the most appropriate method in accordance the specification and integrate it effectively in the process.

• Tool design for the manipulation and positioning of the piece.

• Software development to establish a valid mathematical method for any piece made of composite material.AMCATEMO

OBUU is developing, together with the Research Group HUMLOG from the Operational Research department of the Faculty of Mathematics of Universidad Complutense de Madrid, a new method to help improve the operational performance and reducing the investment in consumable materials. This new mathematical models will be implemented into the Stockwatch platform as soon as they are developed, tested and validated.

OPTIMUS

- Liderado por Airbus e integrado por Obuu , Firmal Trading, Inventia Kinetics, LGAI Technological Center, Metromecánica y Utingal.

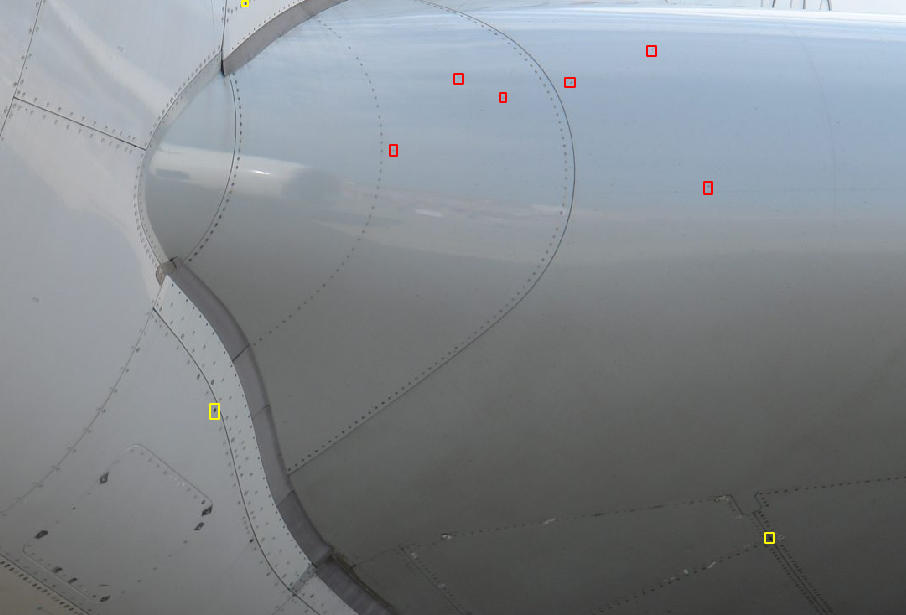

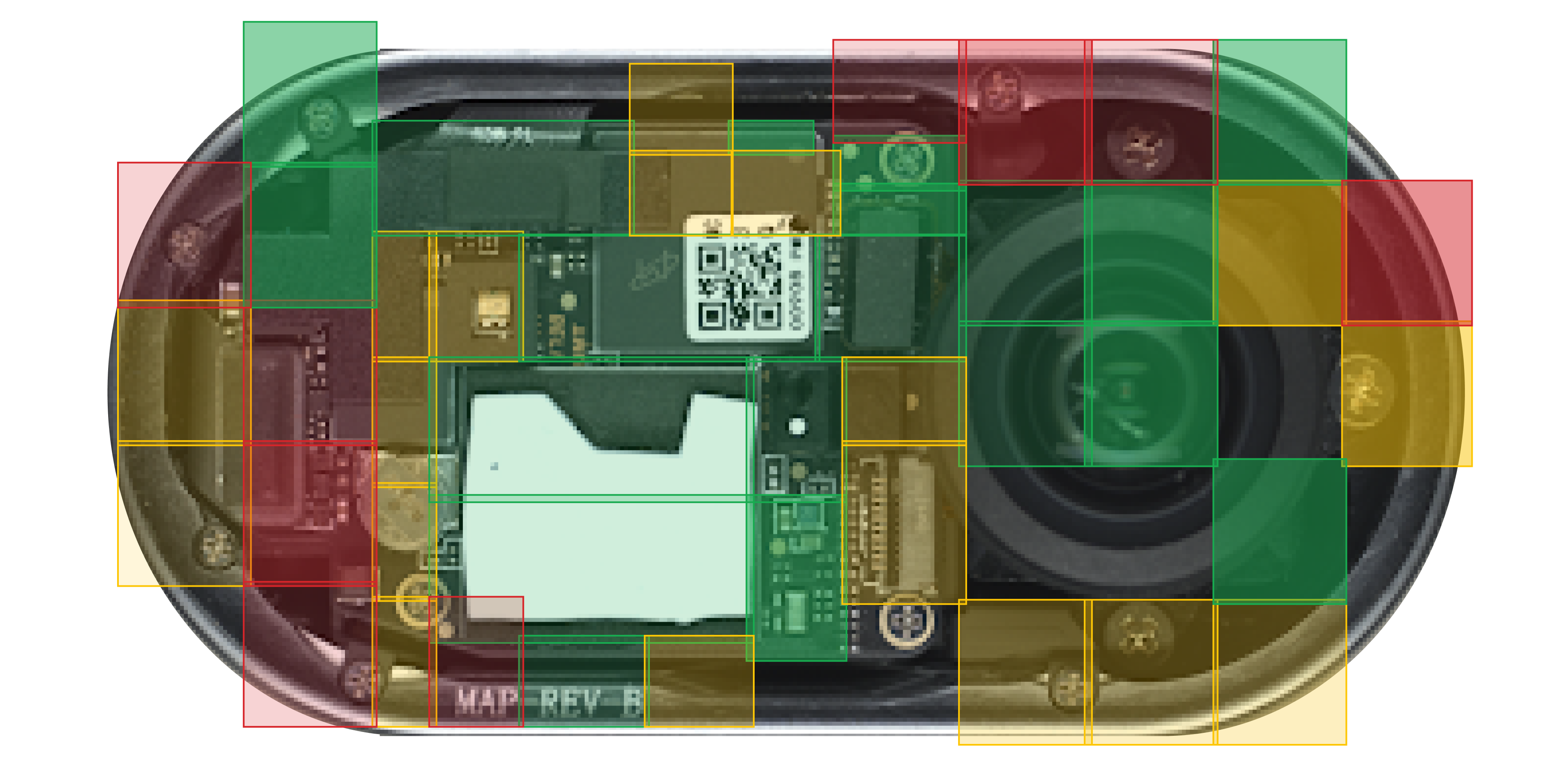

- El cometido de Obuu en el proyecto consiste en el desarrollo de un sistema de detección automática de defectos de fabricación y montaje en pieza de vuelo aeronáutica a través de técnicas de Machine Learning/IA, Visión Computerizada y procesado de imágenes que permita el ahorro de tiempos de inspección de calidad en planta.

- Proyecto subvencionado por el CDTI, apoyado por el ministerio de Ciencia e Innovación y financiado por la Unión Europea – NextGenerationEU.